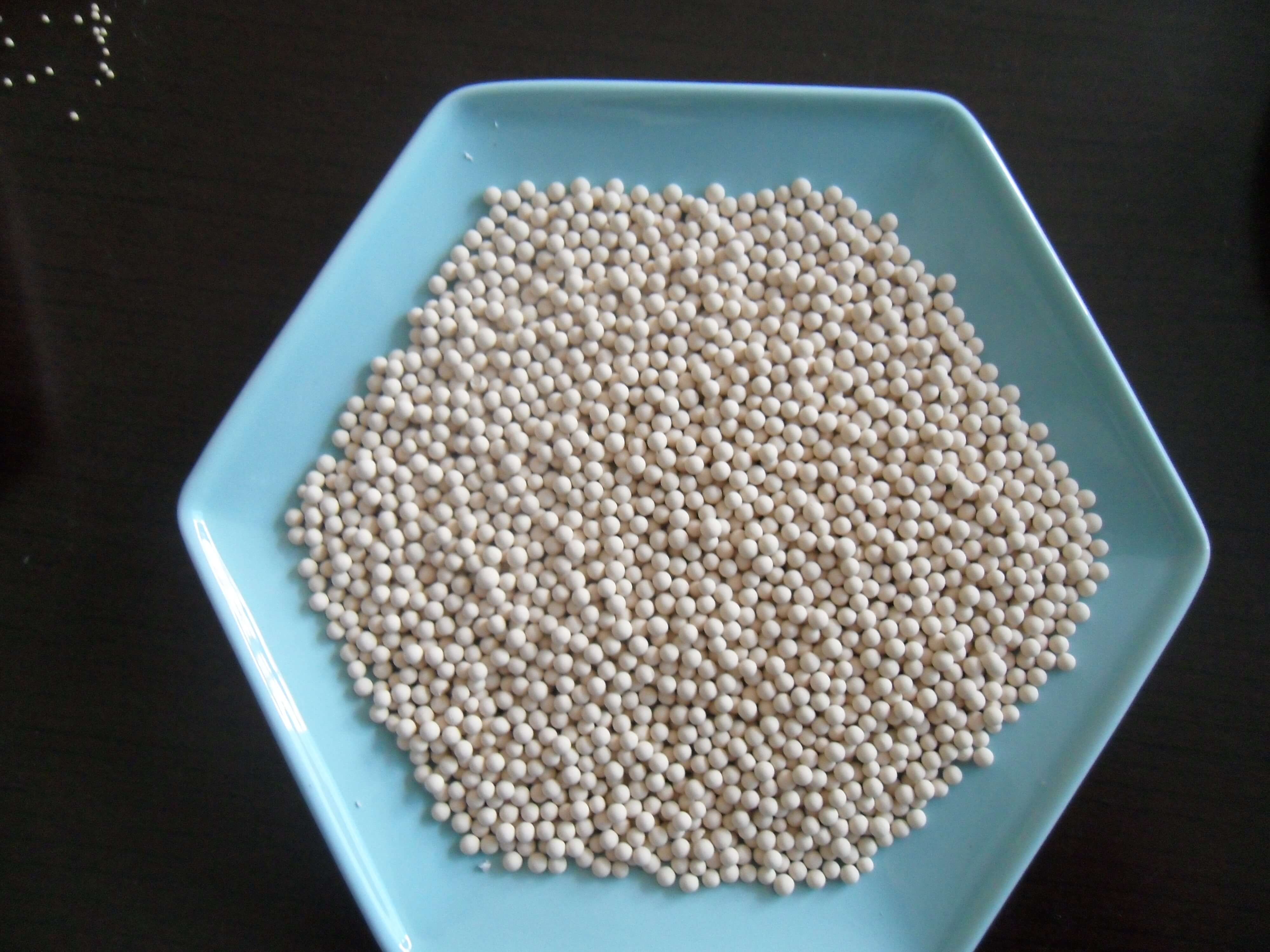

5A molecular sieve can adsorb any molecule smaller than this pore size, and is generally called calcium molecular sieve. In addition to the effects of 3A and 4A molecular sieves, it can also adsorb C3-C4 n-alkanes, ethyl chloride, ethyl bromide, butanol, etc. It can be used in the separation of normal isomers, pressure swing adsorption separation and water Co-adsorption with carbon dioxide. Based on the industrial application characteristics of 5A molecular sieve, the 5A molecular sieve produced by us has high selectivity and fast adsorption speed, and is especially suitable for pressure swing adsorption. It can be adapted to various sizes of pressure swing adsorption devices for oxygen, hydrogen, carbon dioxide, etc. It is a fine product in the pressure swing adsorption industry.

Molecular formula:3/4CaO·1/4Na2O·AI2O3·2SiO2·.9/2H2O

Silicon to aluminum ratio:SiO2/AI2O3≈2

Effective aperture: about 5A

Application: Mainly used for the separation of normal isoparaffin, oxygen and nitrogen separation, drying and refining of chemical industry, petroleum and natural gas, ammonia decomposition gas and other industrial gases and liquids.

Technical index:

|

performance |

unit |

Technical index |

|||

|

shape |

|

article |

ball |

||

|

diameter |

mm |

1.5-1.7 |

3.0-3.3 |

2.0-3.0 |

3.0-5.0 |

|

granularity |

% |

≥98 |

≥98 |

≥98 |

≥98 |

|

Bulk density |

G/ml |

≥0.65 |

≥0.65 |

≥0.70 |

≥0.68 |

|

Wear rate |

% |

≤0.2 |

≤0.3 |

≤0.2 |

≤0.2 |

|

Compressive strength |

N |

≥30/cm |

≥50/cm |

≥60/p |

≥80/p |

|

Static water adsorption |

% |

≥20 |

≥20 |

≥21.5 |

≥21.5 |

|

N-hexane adsorption |

% |

≥12 |

≥12 |

≥14 |

≥14 |

|

Packaging water content |

% |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

Remarks: The above are the commonly used parameters of 5A molecular sieve. Specific to other different uses, the technical indicators will be adjusted. Please contact our company according to the specific application to obtain specific technical data.

regeneration:

1. Dehydration: It depends on the pressure, temperature and water content of the regeneration gas. Generally, the drying gas at 200 ~ 350 ℃ is 0.3 ~ 0.5kg / cm2

Under pressure, pass through the molecular sieve bed for 3 to 4 hours to bring the outlet temperature to 110 to 180 ° C and cool.

2. Deorganization: replace organics with steam, then remove moisture.

Storage: Room temperature, relative humidity is not more than 90%; should not be directly exposed to the air; avoid water, acid, alkali.

Packing: 25KG cardboard drum or bag. Specific according to customer requirements.

Note: Avoid direct exposure of the molecular sieve to the air, affecting the adsorption effect.

Copyright(C)2021,Langfang Naco New Material Technology Co., Ltd. All Rights Reserved.Supported by ChemNet ChinaChemNet Toocle 31fabu Copyright Notice

| |||||||||||||||